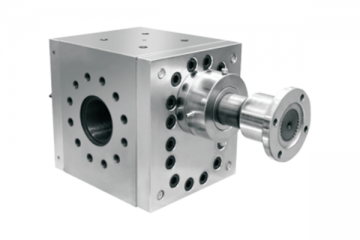

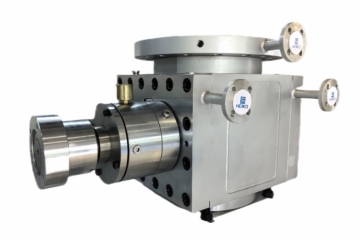

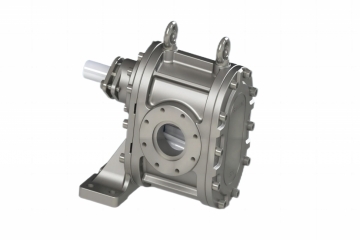

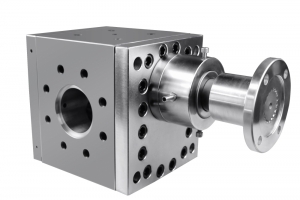

The company's products have reliable quality and stable operation. Correct installation and use are very important. After the connection of gear pump, motor, drive connector, pipeline connector, heating pipeline and circuit is completed, ensure that the connection is tight, the stress of components is uniform, and the circuit meets the requirements of grounding, shielding and explosion-proof. After startup, set the speed at 30R / min and operate for 30 minutes. Observe whether the equipment has abnormal vibration and noise, whether there is material leakage, whether the pressure measurement and temperature measurement instruments display normally, and whether the motor power output is stable without obvious fluctuation. If there is any abnormality, check the cause until the test is normal.

If there is no abnormality in the initial operation of the equipment, switch to conventional production, adjust the motor speed until it is output according to the rated output, and it is not allowed to increase the output at a large high speed, which is prone to pump shaft fracture, seal failure and other faults. After XX hours, stop the machine to replace the packing seal, remove the accumulated material in the spiral groove of the sealing sleeve, and replace the bolts of the transmission parts. Pay close attention to the changes of inlet and outlet pressure, temperature, current and voltage during use and deal with them in time.